JT’s Beer Equipment Page

Rotating Racking Arm Plans

NEW RRA Mk II

You need a lathe to complete this project!

If you don’t have a lathe, see the note below.

NEW and Improved 6-1-07 Please note changed parts list

and drawings.

What I have done is added a feature to allow easy

cleaning of the inside O-Ring

after each batch. No need to disassemble after each batch

for you anal retentive types!

Materials List

|

Quantity |

Description |

Part Number |

Source |

|

1 |

3/8” CPVC Sch80 Threaded 90 |

4589K21 |

McMaster-Carr |

|

1 |

3/8” x 3” CPVC Sch80 Threaded Nipple |

6810K51 |

McMaster-Carr |

|

1 |

3/8” x 8” CPVC Sch80 Threaded Nipple 1 |

6810K81 |

McMaster-Carr |

|

1 |

O-Ring AS568A-209 |

9452K188 |

McMaster-Carr |

|

1 |

O-Ring AS568A-318 |

9452K206 |

McMaster-Carr |

|

1 |

1” Delrin Rod 2 |

8572K61 |

McMaster-Carr |

|

1 |

1 3/8” Delrin Rod 2 |

8572K24 |

McMaster-Carr |

|

1 |

3/4" PVC Female Adapter 2 |

4880K82 |

McMaster-Carr |

|

1 |

PVC Ball Valve 3/8" NPT X 3/8" to 5/8" Barb |

45975K62 |

McMaster-Carr |

1 Cut into two pieces each one threaded on one end with a total length of 3.750” including the

threads if you mount it in the 15 gallon fermenter in the ring. Only one is needed for each RRA

2 Machined as shown on the plans

The

Rotating Racking Arm parts with Bulkhead fitting and valve.

The

Rotating Racking Arm parts with Bulkhead fitting and valve.

O-Ring seals for no leaks and easy turning.

Now with easy cleaning of the inside O-Ring.

This

shows the sub assemblies.

This

shows the sub assemblies.

Shown

here inside of the 15 gallon fermenter.

Shown

here inside of the 15 gallon fermenter.

Shown

here in the cleaning position with the spacer out.

Shown

here in the cleaning position with the spacer out.

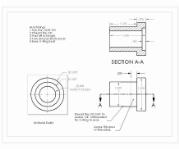

The

first part to machine is the spacer that fits next to the elbow on the 2 ½”

nipple.

The

first part to machine is the spacer that fits next to the elbow on the 2 ½”

nipple.

It’s real simple so no drawing is needed. 0.680” ID x 1” OD x 0.375 long or long enough

to cover the threads of the short nipple. This part puts a smooth surface in place for the

o-ring to seal on.

The

next part is the locking collar for the outside.

The

next part is the locking collar for the outside.

It has the same ID and OD as the spacer.

The

next part is easy too so no drawing is needed.

The

next part is easy too so no drawing is needed.

Take your PVC female adapter and cut the unthreaded part off.

This makes your “nut”. Make sure you thread it on from the

uncut side because the threads are tapered.

The bulkhead fitting drawing… Make sure when you are cutting

the threads you test your “nut” to make sure you got them deep

enough that the “nut” will thread on all the way. I went about

0.110” deep after touching the OD with my threading tool.

I hope you enjoy making these as much as I did designing them. If you feel that my efforts in designing

this needs compensation please do the following. When Christmas is near purchase a toy and take the

time to go and donate it to the Toys for Tots. That way everyone can smile at least once a year…

If you don’t have a lathe I can make a few from time to time. I just need to recover my costs.

The rotating racking arm without a valve is $35 plus shipping. With a PVC valve and barb $45 plus shipping. (sorry but the price of the components has gone up)

Don’t misunderstand me I’m not trying to make a living with these, I make a living designing and

building automation equipment for factories.

I enjoy making things and the challenge of figuring stuff out, but I do need to recover my

cost of making them.

To contact me look on my personal page.

Big John T