Status Labels¶

Status labels are created using a QLabel and setting the Object Name. Status labels come in two forms. A single-status-label like Machine Status only contains one piece of information, such as OFF, RUN, etc.

A multiple-status-label like the axis or joint dictionaries have multiple items and displays for all joints. Multiple-status-labels use a number identifier to select the axis, joint, or spindle information wanted.

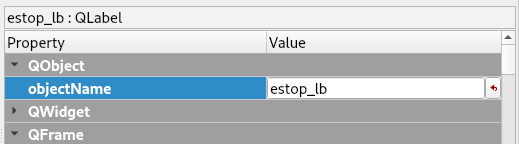

When creating a status label, set the objectName to the status you want to display

Precision¶

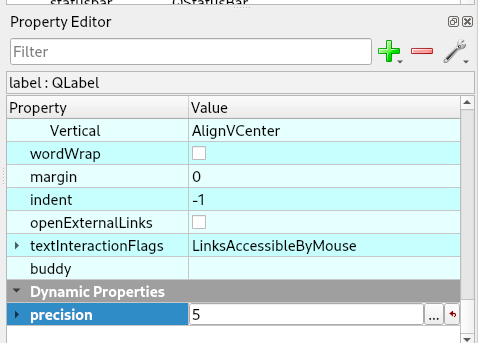

Labels that return float values default to 3 decimal places for metric and 4 for inch.

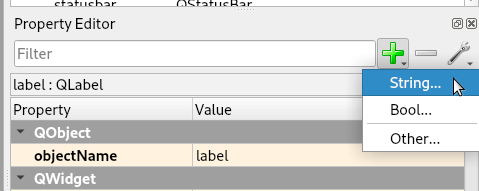

To override the default, select the label then click on the Green Plus sign in the Property Editor to add a Dynamic Property and select String. See Dynamic Properties

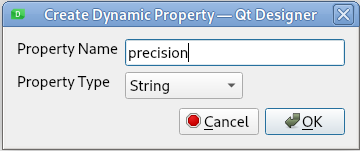

Set the Property Name to precision:

Set the Value to how many decimal places you want for that status label

For more information about status labels read the LinuxCNC Python Interface Status Attributes

Status Labels¶

Status Labels are created by adding a QLabel and changing the Object Name to one of the following. Some status labels use a dictionary to look up the name instead of displaying the integer the name is displayed.

acceleration_lb - returns float

reflects the INI entry [TRAJ]DEFAULT_LINEAR_ACCELERATION, if that entry is not

found it returns 1e+99

active_queue_lb - returns integer

number of motions blending

actual_position_lb - returns tuple of floats

current trajectory position, (x y z a b c u v w) in machine units

See the Axis Position labels for individual axis positions.

adaptive_feed_enabled_lb - returns boolean

status of adaptive feedrate override

ain_lb - returns tuple of floats

current value of the analog input pins

angular_units_lb - returns float - precision can be set

machine angular units per deg, reflects [TRAJ]ANGULAR_UNITS

aout_lb - returns tuple of floats

current value of the analog output pins

axis_lb - returns tuple of dicts

reflecting current axis values

axis_mask_lb - returns integer

sum of the axes by [TRAJ]COORDINATES X=1, Y=2, Z=4, A=8, B=16, C=32, U=64, V=128, W=256

block_delete_lb - returns boolean

block delete current status

call_level_lb - returns integer

current subroutine depth. - 0 If not in a subroutine

command_lb - returns string

currently executing command

current_line_lb - returns integer

currently executing line

current_vel_lb - returns float - precision can be set

current velocity in user units per second

cycle_time_lb - returns float - precision can be set

thread period

debug_lb - returns integer

debug flag from the INI file

delay_left_lb - returns float - precision can be set

remaining time on G4 dwell command in seconds

din_lb - returns tuple of integers

current value of the digital input pins

distance_to_go_lb - returns float - precision can be set

remaining distance of current move as reported by trajectory planner

echo_serial_number_lb - returns integer

The serial number of the last completed command sent by a UI to task.

All commands carry a serial number. Once the command has been executed,

its serial number is reflected in echo_serial_number

enabled_lb - returns boolean

trajectory planner enabled flag

estop_lb - returns integer

Returns either STATE_ESTOP = 1) or not = 0)

exec_state_lb - returns integer that is used to lookup the state name.

task execution state. One of EXEC_ERROR = 1, EXEC_DONE = 2,

EXEC_WAITING_FOR_MOTION = 3, EXEC_WAITING_FOR_MOTION_QUEUE = 4,

EXEC_WAITING_FOR_IO = 5, EXEC_WAITING_FOR_MOTION_AND_IO = 7,

EXEC_WAITING_FOR_DELAY = 8, EXEC_WAITING_FOR_SYSTEM_CMD = 9,

EXEC_WAITING_FOR_SPINDLE_ORIENTED = 10).

feed_hold_enabled_lb - returns boolean

enable flag for feed hold

feed_override_lb - returns boolean

enable flag for feed override

file_lb - returns string

currently loaded G-code filename with path

flood_lb - returns integer that is used to lookup the state of OFF or ON

Flood status, either FLOOD_OFF = 0) or FLOOD_ON = 1)

g5x_index_lb - returns integer that is used to lookup the coordinate system name

currently active coordinate system, G54=1, G55=2 etc

g5x_offset_lb - returns tuple of floats

offsets of the currently active coordinate system X, Y, Z, U, V, W, A, B, C

gcodes_lb - returns tuple of integers

Active G-codes for each modal group.

The integer values reflect the nominal G-code numbers multiplied by 10.

(Examples: 10 = G1, 430 = G43, 923 = G92.3)

homed - returns tuple of integers

currently homed joints, 0 = not homed, 1 = homed

See the Axis Homed labels for individual axis home status.

id - returns integer

currently executing motion id

ini_filename_lb - returns string

path to the INI file passed to linuxcnc

inpos_lb - returns boolean

machine-in-position flag

input_timeout_lb - returns boolean

flag for M66 timer in progress

interp_state_lb - returns integer that is used to lookup the state name

current state of RS274NGC interpreter. One of INTERP_IDLE = 1,

INTERP_READING = 2, INTERP_PAUSED = 3, INTERP_WAITING = 4

interpreter_errcode_lb - returns integer that is used to lookup the error name

current RS274NGC interpreter return code

INTERP_OK = 0,

INTERP_EXIT = 1,

INTERP_EXECUTE_FINISH = 2,

INTERP_ENDFILE = 3,

INTERP_FILE_NOT_OPEN = 4,

INTERP_ERROR = 5

joint - returns tuple of dicts

reflecting current joint values

See the Joint Status labels for individual joint status items.

joint_actual_position - returns tuple of floats

actual joint positions

joint_position - returns tuple of floats

desired joint positions

joints_lb - returns integer

number of joints. Reflects [KINS]JOINTS INI value

kinematics_type_lb - returns integer that is used to lookup the kinematics name

The type of kinematics

KINEMATICS_IDENTITY = 1

KINEMATICS_FORWARD_ONLY = 2

KINEMATICS_INVERSE_ONLY = 3

KINEMATICS_BOTH = 4

limit - returns tuple of integers

axis limit masks. minHardLimit=1, maxHardLimit=2, minSoftLimit=4, maxSoftLimit=8

linear_units_lb - returns float - precision can be set

machine linear units per mm, reflects [TRAJ]LINEAR_UNITS INI value

lube_lb - returns integer

lube on flag

lube_level_lb - returns integer

reflects iocontrol.0.lube_level

max_acceleration_lb - returns float - precision can be set

maximum acceleration. Reflects [TRAJ]MAX_ACCELERATION

max_velocity_lb - returns float - precision can be set

maximum velocity. Reflects the current maximum velocity. If not modified by

halui.max-velocity or similar it should reflect [TRAJ]MAX_VELOCITY

min_jog_vel_lb - returns int

minimum jog velocity slider setting. Reflects the [DISPLAY] MIN_LINEAR_VELOCITY

setting in user units per minute.

max_jog_vel_lb - returns int

maximum jog velocity slider setting. Reflects the [DISPLAY] MAX_LINEAR_VELOCITY

setting in user units per minute.

mcodes_lb - returns tuple of 10 integers

currently active M-codes

mist_lb - returns integer

Mist status, either MIST_OFF = 0 or MIST_ON = 1

motion_line_lb - returns integer

source line number motion is currently executing

motion_mode_lb - returns integer that is used to lookup the motion mode name

This is the mode of the Motion controller.

TRAJ_MODE_FREE = 1

TRAJ_MODE_COORD = 2

TRAJ_MODE_TELEOP = 3

motion_type_lb - returns integer that is used to lookup the motion type name

The type of the currently executing motion. One of:

MOTION_TYPE_TRAVERSE = 1

MOTION_TYPE_FEED = 2

MOTION_TYPE_ARC = 3

MOTION_TYPE_TOOLCHANGE = 4

MOTION_TYPE_PROBING = 5

MOTION_TYPE_INDEXROTARY = 6

Or 0 if no motion is currently taking place.

optional_stop_lb - returns integer

option stop flag

paused_lb - returns boolean

motion paused flag

pocket_prepped_lb - returns integer

A Tx command completed, and this pocket is prepared. -1 if no prepared pocket

position - returns tuple of floats

trajectory position

probe_tripped_lb - returns boolean

True if probe has tripped

probe_val_lb - returns integer

reflects value of the motion.probe-input pin

probed_position_lb - returns tuple of floats

position where probe tripped

probing_lb - returns boolean

True if a probe operation is in progress

program_units_lb - returns integer that is used to lookup the units name

CANON_UNITS_INCHES = 1,

CANON_UNITS_MM = 2,

CANON_UNITS_CM = 3

queue_lb - returns integer

current size of the trajectory planner queue

queue_full_lb - returns boolean

the trajectory planner queue is full

rapid_override_lb - returns percent

rapid override percent

rapidrate_lb - returns float - precision can be set

rapid override scale, 1.0 = 100%

read_line_lb - returns integer

line the RS274NGC interpreter is currently reading

rotation_xy_lb - returns float - precision can be set

current XY rotation angle around Z axis

settings_lb - returns tuple of floats

current interpreter settings

settings[0] = sequence number

settings[1] = feed rate

settings[2] = speed

settings[3] = G64 P blend tolerance

settings[4] = G64 Q naive CAM tolerance

spindles_lb - returns tuple of dicts

returns the current spindle status

state_lb - returns integer that is used to lookup the state name

current command execution status

One of RCS_DONE = 1, RCS_EXEC = 2, RCS_ERROR = 3

task_mode_lb - returns integer that is used to lookup the task mode name

current task mode

One of MODE_MANUAL = 1, MODE_AUTO = 2, MODE_MDI = 3

task_paused_lb - returns integer

task paused flag, not paused = 0, paused = 1

task_state_lb - returns integer that is used to lookup the task state name

current task state

One of STATE_ESTOP = 1, STATE_ESTOP_RESET = 2, STATE_OFF = 3 STATE_ON = 4

STATE_OFF is never seen

tool_in_spindle_lb - returns integer

current tool number in spindle (0 if no tool loaded)

tool_from_pocket_lb - returns integer

pocket number for the currently loaded tool (0 if no tool loaded)

tool_offset_lb - returns tuple of floats

offset values of the current tool

tool_table_lb - returns tuple of tool_results

list of tool entries. Each entry is a sequence of the following fields: id,

xoffset, yoffset, zoffset, aoffset, boffset, coffset, uoffset, voffset,

woffset, diameter, frontangle, backangle, orientation. The id and orientation

are integers and the rest are floats.

If id = -1 no tools are in the tool table.

Note

You don’t have to use all the labels; only use the ones you need.

Axis Status¶

The Axis status contains status items for all 9 axes. Replace the n with the number of the axis. Axis numbers start at 0 and go through 8. Returns a float

axis_n_max_position_limit_lb |

axis_n_min_position_limit_lb |

axis_n_velocity_lb |

axis_n_vel_per_min_lb |

Note

The Axis velocity label only reports back jogging speed; use the joint velocity label for linear speed.

Joint Status Labels¶

The Joint status contains status items for 16 joints. Replace the n with the number of the joint. Joint numbers start at 0 and go through 15

joint_backlash_n_lb |

joint_input_n_lb |

joint_min_position_limit_n_lb |

joint_enabled_n_lb |

joint_jointType_n_lb |

joint_in_soft_limit_n_lb |

joint_fault_n_lb |

joint_max_ferror_n_lb |

joint_output_n_lb |

joint_ferror_current_n_lb |

joint_max_hard_limit_n_lb |

joint_override_limits_n_lb |

joint_ferror_highmark_n_lb |

joint_max_position_limit_n_lb |

joint_units_n_lb |

joint_homed_n_lb |

joint_max_soft_limit_n_lb |

joint_vel_sec_n_lb |

joint_vel_min_n_lb |

joint_homing_n_lb |

joint_min_ferror_n_lb |

joint_inpos_n_lb |

joint_min_hard_limit_n_lb |

Special Labels¶

Run from line label start_line_lb

Axis Position Labels¶

Axis machine position labels (no offsets.) Returns a float

actual_lb_x |

actual_lb_y |

actual_lb_z |

actual_lb_a |

actual_lb_b |

actual_lb_c |

actual_lb_u |

actual_lb_v |

actual_lb_w |

Axis position labels including all offsets. Returns a float

dro_lb_x |

dro_lb_y |

dro_lb_z |

dro_lb_a |

dro_lb_b |

dro_lb_c |

dro_lb_u |

dro_lb_v |

dro_lb_w |

Axis Distance to Go labels¶

dtg_lb_x |

dtg_lb_y |

dtg_lb_z |

dtg_lb_a |

dtg_lb_b |

dtg_lb_c |

dtg_lb_u |

dtg_lb_v |

dtg_lb_w |

Axis Homed Labels¶

home_lb_0 |

home_lb_1 |

home_lb_2 |

home_lb_3 |

home_lb_4 |

home_lb_5 |

home_lb_6 |

home_lb_7 |

home_lb_8 |

Offset Labels¶

Offsets for the currently active G5x coordinate system. Returns a float

g5x_lb_x |

g5x_lb_y |

g5x_lb_z |

g5x_lb_a |

g5x_lb_b |

g5x_lb_c |

g5x_lb_u |

g5x_lb_v |

g5x_lb_w |

Offsets for G92. Returns a float

g92_lb_x |

g92_lb_y |

g92_lb_z |

g92_lb_a |

g92_lb_b |

g92_lb_c |

g92_lb_u |

g92_lb_v |

g92_lb_w |

Velocity Labels¶

Tool velocity using two perpendicular joint velocities.

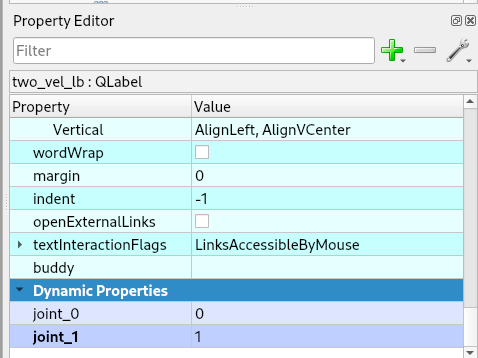

Name the label two_vel_lb and add two int type Dynamic Properties called joint_0 and joint_1 and set the values to the perpendicular joint numbers you want to calculate. Typically this would be for the X and Y axes.

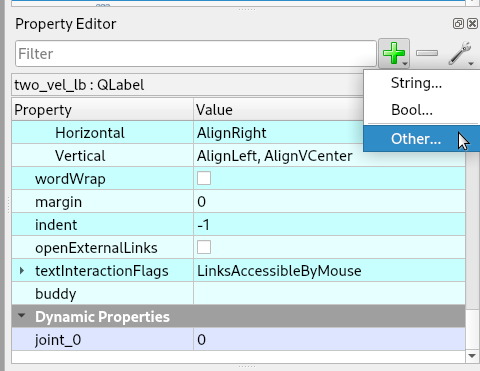

To select an int type of Dynamic Property, select Other after clicking on the green plus sign

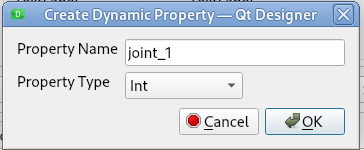

Then select the Property Type of int

The two Dynamic Properties should look like this

Tool velocity using three perpendicular joint velocities.

Name the label three_vel_lb and add three int type Dynamic Properties called joint_0, joint_1 and joint_2 and set the values to the perpendicular joint numbers you want to calculate. Typically this would be for the X, Y and Z axes.

I/O Status¶

The I/O status contains status items for 64 I/O’s. Replace the n with the number of the I/O. I/O numbers start at 0 and go through 63. Analog I/O returns a float. For example a QLabel with an object name of din_5_lb will show the status of the motion.digital-in-05 HAL pin

HAL Pin |

Label Name |

motion.analog-in-nn |

ain_n_lb |

motion.analog-out-nn |

aout_n_lb |

motion.digital-in-nn |

din_n_lb |

motion.digital-out-nn |

dout_n_lb |